Power Transformers – 500 kVA to 250+ MVA, Up to 230kV Class | Integrated Power & Engineering

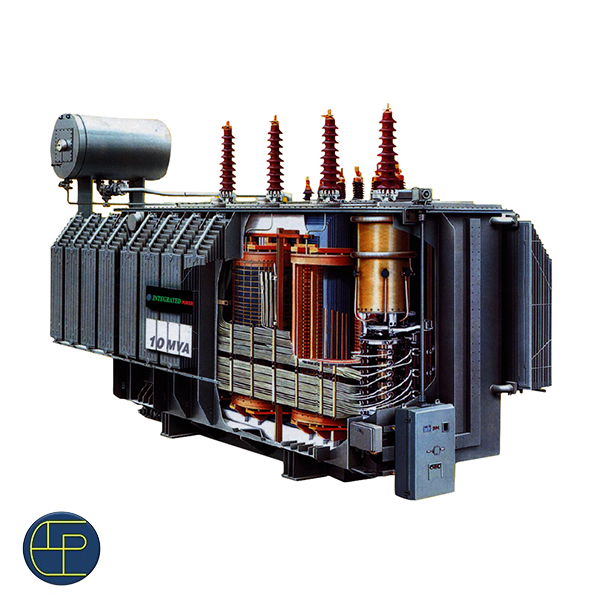

At Integrated Power & Engineering, we manufacture and supply high-performance Power Transformers engineered for reliable high-voltage energy transfer across utility substations, transmission interfaces, renewable energy plants, and heavy-duty industrial networks. Built with premium materials, proven insulation systems, and robust mechanical design, our transformers ensure low losses, stable voltage transformation, and long service life—even under fluctuating grid conditions and heavy loading.

Product Overview: Reliable High-Voltage Energy Transfer

A Power Transformer transfers large amounts of electrical energy between voltage levels with maximum efficiency—helping reduce transmission losses and ensuring stable system operation. Unlike standard distribution transformers, power transformers are typically applied where higher capacity, higher voltage class, enhanced cooling, and tighter performance requirements are needed.

Integrated Power & Engineering designs power transformers to support:

- Stable operation under variable load and voltage conditions

- Efficient performance through low no-load and load losses

- Strong short-circuit withstand and mechanical rigidity

- Grid reliability with tap control and protection-ready accessories

Key Specifications (Technical Data)

Power Rating

- 500 kVA to 5,000 kVA (common substation/industrial range)

- Up to 250+ MVA (utility and high-capacity projects on request)

Voltage Class

- 33 kV / 66 kV (standard offerings)

- Higher voltage projects available up to 230 kV class (project dependent)

Typical Voltage Ratios (Examples)

- 33 kV / 11 kV

- 66 kV / 11 kV

- 33 kV / 6.6 kV

- 66 kV / 6.6 kV

- Other ratios available as per utility/consultant specification

Frequency

- 50 Hz

Cooling Methods

- ONAN (Oil Natural Air Natural) – standard cooling

- ONAF (Oil Natural Air Forced) – for higher load demand

- OFAF / ODAF – available on request for heavy-duty and higher MVA applications

Tap Changer Options

- OLTC (On-Load Tap Changer) – for voltage regulation during operation

- DETC (Off-circuit Tap Changer) – for periodic/seasonal adjustment

Core & Windings

- High-grade CRGO core for low losses

- Copper or Aluminum windings (as per design and client requirement)

Insulation System / Thermal Class

- Standard oil-paper insulation (commonly Class A for oil-immersed transformers)

- Enhanced insulation/thermal performance options available based on site and duty requirement

Protection & Accessories (Typical)

- Buchholz relay, PRV, oil level gauge

- OTI/WTI (oil/winding temperature indicators)

- Breather, valves, alarm/trip contacts

- Optional online monitoring (project based)

Standards & Compliance

Designed to meet applicable requirements including:

- IEC 60076 (Power Transformers)

- IEC / ANSI / IS standards (as applicable)

- Utility and consultant project specifications

Key Features & Performance Advantages

1) High Efficiency & Low Loss Design

Optimized magnetic core and winding design reduce:

- No-load losses (core losses)

- Load losses (winding losses)

Improving overall efficiency and lowering lifecycle operating costs.

2) Grid-Ready Reliability Under Heavy Duty

Engineered for stable performance under:

- Fluctuating grid conditions

- Peak loading and continuous duty

- Switching transients and system disturbances

Helping protect downstream equipment and improve system stability.

3) Custom-Engineered to Your Project

We tailor transformer design based on your SLD, load, and utility requirements:

- Voltage ratio, vector group, impedance

- Cooling stage selection and fan control

- Tap range and tap changer selection

- Termination/bushing arrangement

- Protection and monitoring package

4) Robust Construction & Short-Circuit Strength

Designed for strong mechanical endurance through:

- Reliable clamping and bracing

- Winding stability and rigid structure

- Short-circuit withstand capability as per standards and system fault levels

5) Built to Last

High-grade materials, strong insulation coordination, and quality manufacturing ensure decades of dependable service life with reduced maintenance burden.

Typical Applications

- Utility Substations (grid interface and primary distribution)

- High-Voltage Transmission/Distribution Networks

- Renewable Energy Plants (solar/wind evacuation and grid connection)

- Industrial Facilities with heavy power demand

- Large Commercial & Infrastructure Projects (airports, rail/metro, campuses)

Why Choose Integrated Power & Engineering?

- High-grade materials: CRGO cores, copper/aluminum windings

- Quality assurance: routine/type/special testing as per applicable standards

- Custom solutions: aligned with voltage, site, and protection system requirements

- Local engineering support: service and technical support from Bangladesh-based team

- Project-focused delivery: documentation, compliance, and commissioning readiness support